Safety Capacity Reinforcement

Risk Assessment Expert Program

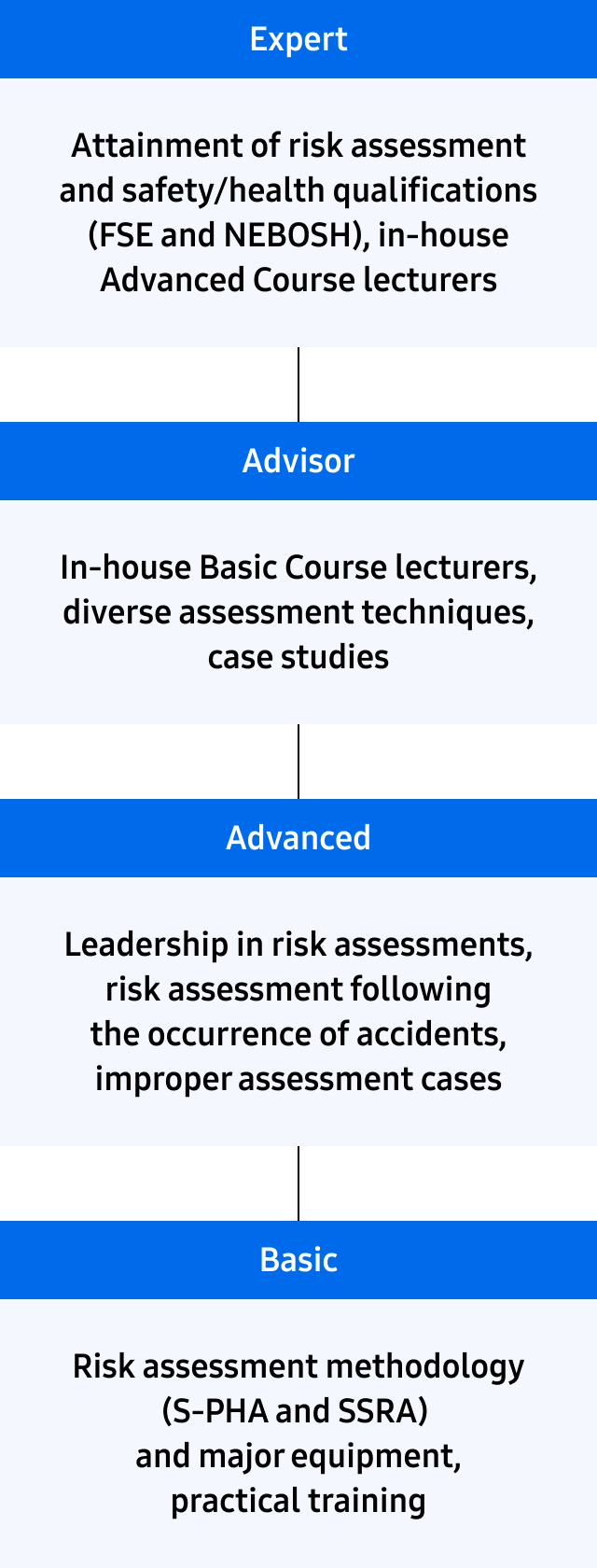

Samsung Electronics operates a risk assessment expert program to reinforce our employees’ safety risk assessment capabilities. In 2024, we trained 956 of DX Division and 2,165 DS Division (1,365 in occupational risk assessment and 800 in process risk assessment).

Safety-Sensitive Culture Promotion Group

DS Division continues to participate in and promote the Safety-Sensitive Culture Promotion Group organized by the Ministry of Employment and Labor. This group brings together a range of institutions including public institutions, labor-management organizations, and enterprises to foster a nationwide safety culture movement. In collaboration with the Gyeonggi District Employment and Labor Office, we produce and distribute content on on-site safety practices and conduct campaigns to raise safety awareness among employees and suppliers.

Global Manufacturing and Workplace Safety Innovation Day

To enhance the safety of our business sites, we have organized EHS Innovation Day each year since 2013 to share and encourage the application of best practices.

DX Division hosts the Global EHS Innovation Day to promote the upward leveling of environmental, health, and safety (EHS) and foster communication among employees at worksites, overseas subsidiaries, and affiliated companies. Since 2015, we have held a separate DX Global EHS Partner Day for major suppliers to share and benchmark the best EHS practices from both our company and suppliers.

Since 2019, the event has been integrated into the DX Global Manufacturing & EHS Innovation Day to maximize synergy with manufacturing technology. It provides an opportunity to gain insights and benchmark EHS through presentations and exhibitions of best practices, such as applying new EHS technologies in the field and establishing our unique safety culture.

Since 2019, DS Division has hosted integrated Manufacturing and Environmental Safety Innovation Day with five affiliates that have similar manufacturing processes and business operations to elevate the safety level of facilities. Through this event, DS Division actively shares common risks and challenges with its affiliate companies regarding environmental safety in manufacturing processes and infrastructure, driving improvements across the board.

In 2024, 45 innovative cases in manufacturing and environmental safety were exhibited, with a focus on advanced technologies based on automation and systems, such as autonomous drones and Digital Twin. The event provided a platform for mutual benchmarking and knowledge exchange.

Environmental Safety Innovation Day, which is centered on expert collaboration and technological exchange, forms part of Samsung’s ongoing efforts to develop environmental safety technology and support future competitiveness.

Safety Training for Employees

In order to enhance the emergency response capabilities of all of our employees and take full advantage of the AEDs installed at our business sites, we made CPR and AED training regular. Health and safety trainings, safety leadership training for executives, and seminars for staff members in charge of safety are being conducted, as well as safety events and safety campaigns to embed safety in all aspects of our business operations.

| Training Target |

Details | 2024 Performance |

|---|---|---|

| Employees | Introductory training, legally required basic training, and safety leadership training for executives | [DX Division]

|

| Staff in charge of environment/ safety (Korea) |

Internal auditor training, specialist cultivation training, legally required continuing training |

|

| Staff in charge of environment/ safety (Global) |

Training developed by individual sites |

|