Supplier Capacity-Building

Training System

In 2023, we placed priority on building suppliers’ capacities in sustainability management in areas including climate action, resource circularity, labor and human rights, and compliance with legal and social responsibilities.

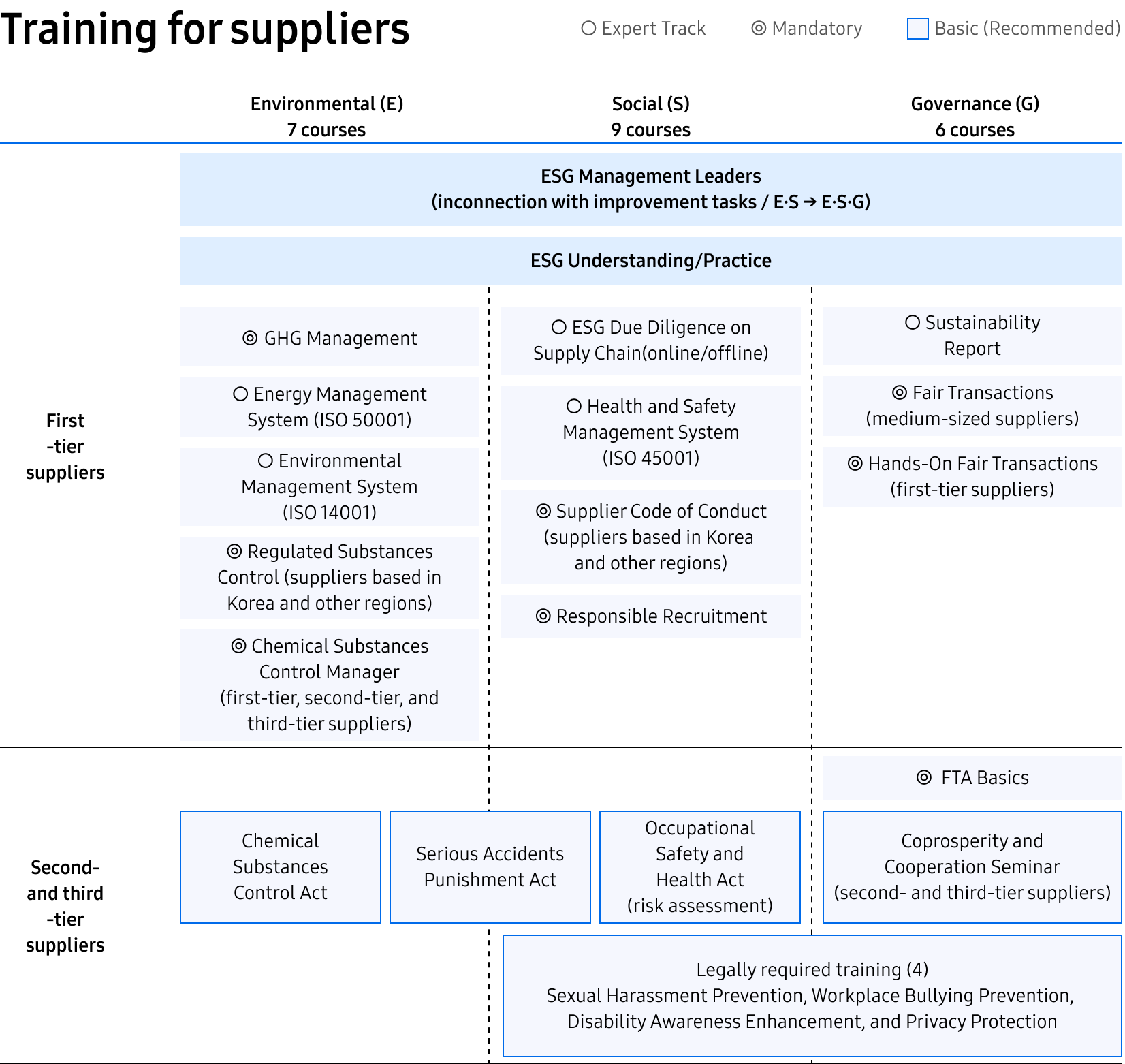

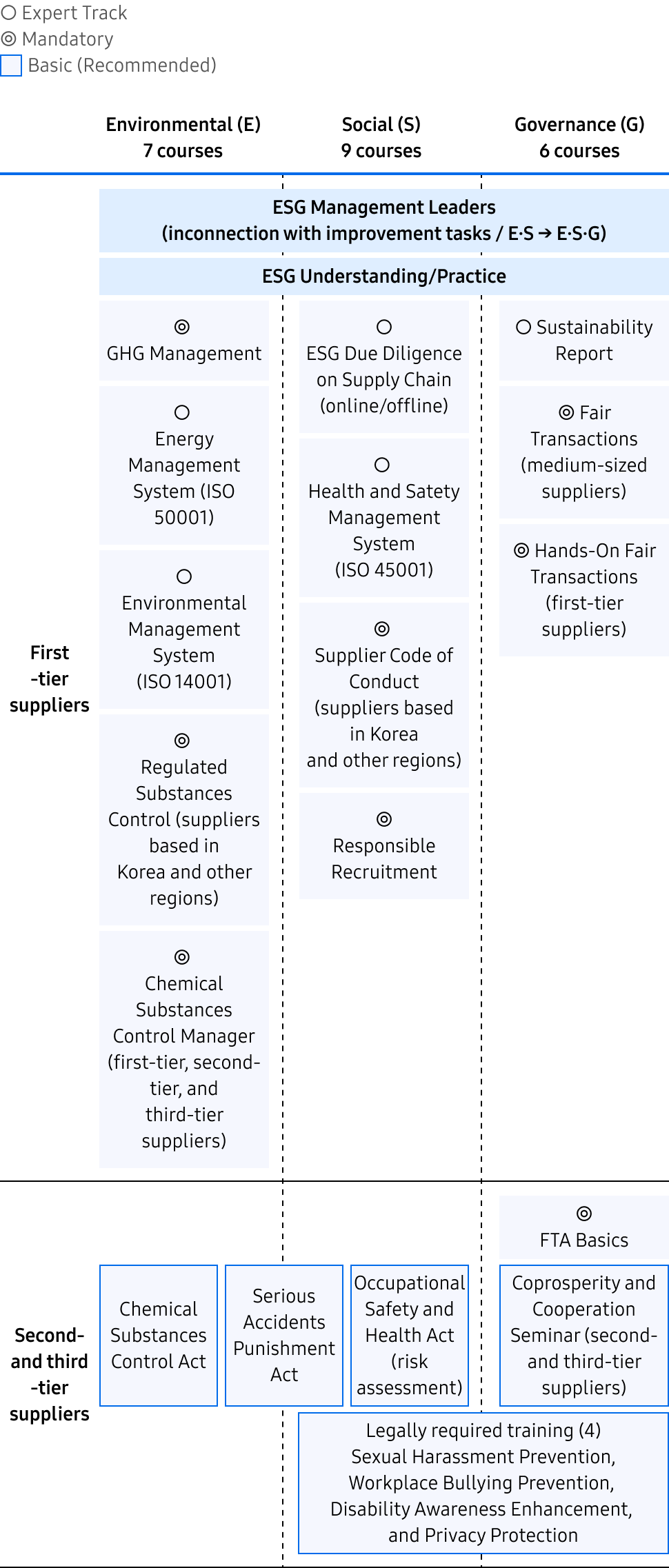

In line with our sustainability-related policies, we have developed training programs for our suppliers to help them meet global standards in Environmental, Social, and Governance (ESG) disclosure and prepare for regulations such as the Corporate Sustainability Due Diligence Directive (CSDDD) in Europe. We strive to raise awareness of the importance of sustainable practices and build their capacities on the ground in managing greenhouse gas emissions, conducting supply chain due diligence, operating Environmental, Health and Safety (EHS) management systems, and publishing sustainability reports, among others. Moreover, legally mandatory courses are offered online which are becoming available to our second- and third-tier suppliers that have signed fair trade agreements with us. To ensure comprehensive adoption of the Supplier Code of Conduct and the forced labor policies across the supply chain, first-tier suppliers are also encouraged to disseminate training content to their sub suppliers and manage risks within the lower tiers of the supply chain.

We also conducted satisfaction surveys among suppliers who had completed the training to measure its effectiveness and identify areas for improvement in the next iteration. In the 2024 ESG Due Diligence on Supply Chain course, suppliers received training on the Supplier Code of Conduct, the Responsible Business Alliance (RBA) audit process, and common compliance violations observed during audits. The participants found detailed guidance and practical examples helpful in their overall understanding and implementation of sustainability principles in their operations.

Samsung Electronics runs various training programs which help to regularly disseminate the Supplier Code of Conduct and uphold the labor and human rights of workers employed by our suppliers. In 2024, the ESG Due Diligence on Supply Chains online course was introduced to enhance first-tier suppliers' ability to oversee and assess their lower-tier suppliers. Furthermore, training programs previously limited to high-risk suppliers, such as Supplier Code of Conduct and Responsible Recruitment, were expanded to include all first-tier suppliers.

Training for suppliers

Labor and Human Rights Training for Suppliers

[DX Division]| Course | Content | Target | Frequency | Completion Rate | |

|---|---|---|---|---|---|

| ESG Due Diligence on Supply Chains |

Offline | Understanding RBA and audit processes | First-tier suppliers in South Korea subject to third-party audits for the year | Twice a year | 100% |

| Labor and human rights, ethics, environment, health and safety, and management systems (The 5 core RBA principles) | |||||

| Violation criteria | |||||

| Areas for improvement and best practices | |||||

| Worker interview practice | |||||

| Online | Understanding RBA and audit processes | First-tier suppliers in South Korea | Once a year | 80% | |

| Labor and human rights, ethics, environment, health and safety, and management systems (The 5 core RBA principles) | |||||

| Violation criteria | |||||

| Areas for improvement and best practices | |||||

| Supplier Code of Conduct |

Online | Labor and human rights, ethics, environment, health and safety, and management systems (The 5 core RBA principles) | First-tier suppliers | Once a year | 100% |

| Responsible Recruitment | Online | Recruitment standards for protecting migrant workers | Suppliers outside of South Korea | Once a year | 90% |

| Identification and assessment | |||||

| Corrective actions | |||||

| Prevention and mitigation | |||||

| Course | Content | Target | Frequency | Training Results |

|---|---|---|---|---|

| ESG Due Diligence on Supply Chains | Understanding RBA-based processes in Samsung Electronics Supplier Code of Conduct | DS Division's purchasing and on-site suppliers | Twice a year | Completed by 769 trainees in 2023 and 962 trainees in 2024 |

| Labor and human rights, health and safety, environment, and supply chain | ||||

| Areas for improvement and best practices |

In 2021, Samsung Electronics launched the Responsible Recruitment Procedure training course. This course equips suppliers with the knowledge to recruit migrant workers responsibly and mitigate risks in their organization. We assist first-tier suppliers in enforcing Samsung Electronics’ forced labor prevention policies within their sub-supply chains by helping them identify potential forced labor instances throughout the entire recruitment process. This involves scrutinizing recruitment agencies connecting sending country to the receiving country, conducting due diligence, and using a self-diagnostic tool to identify risks.

In October 2023, our Malaysian subsidiary invited the International Organization for Migration (IOM) to train 56 human resources representatives from 41 first-tier suppliers. This initiative aimed to combat forced labor among migrant workers. The training provided guidance on the potential risks of forced labor at each stage of recruitment, examples of various forms of forced labor, crucial considerations when contracting a recruitment agency, and raising awareness about protecting migrant workers’ labor and human rights.

In 2024, we trained 2,238 labor and human rights personnel* from 1,355 suppliers on topics ranging from recruitment criteria to risk identification, assessment, improvement, prevention, and mitigation. To improve local workers’ understanding, we also provided training in local languages including English, Chinese, Thai, and Malay.

Training Details

Correcting and supplementing suppliers’ policies based on the provisions related to forced labor prohibition in the Supplier Code of Conduct

Assessing the entire recruitment process to arrive at suppliers, covering recruitment agencies in the sending country and the receiving country, with suppliers utilizing a self-diagnosis tool to conduct risk assessments

Collecting data and analyzing it through migrant worker interviews, grievance handling, and other methods, and establishing improvement plans

Analyzing root causes, establishing corrective measures, and performing training for migrant workers and recruitment agencies

Since 2015, each manufacturing site of Samsung Electronics has held annual training sessions and workshops for the heads and working-level staff of supplier subsidiaries, focusing on the Supplier Code of Conduct and key human rights risks by country. In 2024, a total of 2,046 participants* from 1,227 global suppliers took part in the training.

- Updates on global and local regulations, supplier audit results, and improvement cases

- Prohibition of forced labor, mutual respect, humane treatment, and non-discrimination based on the Samsung Electronics Supplier Code of Conduct

- Management and assessment of lower-tier suppliers

- Human rights practices in organizational culture, HR operations, and labor-management relations

- Diversity, Equity, and Inclusion (DEI)

- Training content distribution to sub suppliers by participating suppliers, emphasizing the Samsung Electronics Supplier Code of Conduct

Samsung Electronics provides its purchasing staff with ongoing online training on labor and human rights, including the elimination of forced labor in suppliers. In 2024, 102 purchasing staff members* completed the Supplier Management course, which covers supplier inspections and compliance practices.

To highlight the importance of labor rights in supplier management, new and transferred purchasing staff are required to complete the Purchasing Onboarding Training, a mandatory in-person course held twice a year. This training covers key topics such as Samsung Electronics Supplier Code of Conduct, supplier audits and improvements, worker grievance handling, and global sustainability trends. In 2024, 44 staff members completed this course.